Clutch Replacement

|

Special Tools Required

Clutch alignment tool set

07PAF-0020000

Ring gear holder

07LAB-PV00100

Sliding hammer weight

07741-0010201

Driver handle, 15 x 135 L

07749-0010000

Bearing remover shaft 15

07936-KC10100

Bearing remover head 15

07936-KC10200

Bearing driver attachment, 28 x 30 mm

07946-1870100

Engine Side

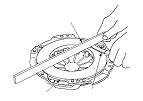

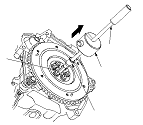

Pressure Plate Inspection and Removal

|

|

|

|

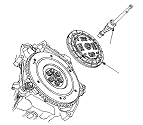

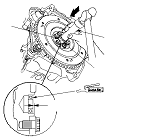

Clutch Disc Inspection and Removal

|

|

|

|

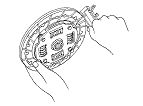

Flywheel Inspection

|

|

Flywheel Replacement

|

|

|

Pilot Bearing Inspection

|

|

Pilot Bearing Replacement

|

|

|

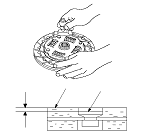

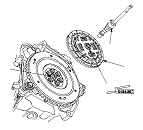

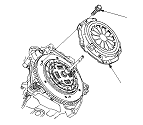

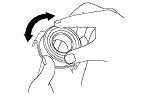

Clutch Disc and Pressure Plate Installation

|

|

|

|

Transmission Side

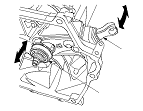

Release Bearing Removal

|

|

Release Bearing Inspection

|

|

Release Bearing Installation

|

|