How to Troubleshoot the Fuel and Emissions Systems

|

CHECK ENGINE OIL LEVEL display (A) Indication

If display is on, engine oil level may have had a failure.

Check the engine oil level sensor.

|

|

How to Use the HDS (Honda Diagnostic System)

If the MIL (malfunction indicator lamp) has come on

|

|

|

If the MIL did not stay on

If the MIL did not stay on but there is a driveability problem, do the symptom troubleshooting.

|

|

Scan Tool Clear Command

If you are using a generic scan tool to clear commands, be aware that there is only one setting for clearing the ECM/PCM, and it clears all commands at the same time (CKP pattern learn, idle learn, freeze data, on-board snapshot, and DTCs). After you clear all commands, you then need to do these procedures, in this order:

ECM/PCM idle learn procedure;

CKP pattern learn procedure.

|

|

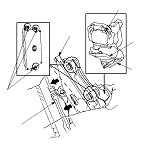

CKP Pattern Clear/CKP Pattern Learn

Clear/Learn Procedure (with the HDS)

Learn Procedure (without the HDS)

|

|

|

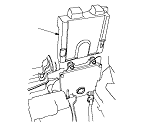

Substituting the ECM/PCM

Special Tools Required

NOTE: Use this procedure when you have to substitute a known-good ECM/PCM during troubleshooting procedure.

|

|