|

DTC 51-01:

Torque Sensor (VT1 and VT2) (Regular Diagnosis)

DTC 51-02:

Torque Sensor VT3 Differential-amplification Function (Regular Diagnosis)

DTC 51-03:

Torque Sensor (VT1, VT2 Rapid-change) (Regular Diagnosis)

DTC 51-04:

Torque Sensor (Temperature) (Regular Diagnosis)

DTC 51-05:

Torque Sensor (Coil) (Regular Diagnosis)

-

Turn the ignition switch to ON (II).

-

Clear the DTC with the HDS.

-

Turn the ignition switch to LOCK (0).

-

Start the engine.

-

Turn the steering wheel from lock to lock several times, and hold the steering wheel for 10 seconds or more.

-

Check for DTCs with the HDS.

|

Is DTC 51-01, 51-02, 51-03, 51-04, or 51-05 indicated?

|

|

YES

|

-

|

|

|

NO

|

-

|

Intermittent failure, the system is OK at this time. Check for poor connections or loose terminals at the EPS motor and the EPS control unit.■

|

-

Turn the ignition switch to LOCK (0).

-

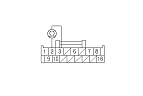

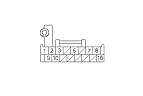

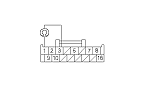

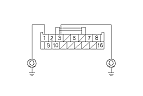

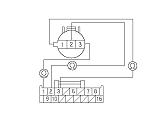

Disconnect the EPS control unit connector C (16P).

-

Measure the resistance between EPS control unit connector C (16P) terminals No. 2 and No. 3.

|

Is there resistance 10 Ω or less at 20 °C (68 °F)?

|

-

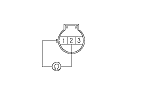

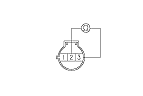

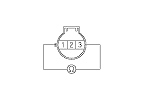

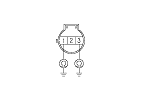

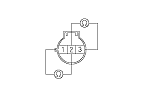

Disconnect the torque sensor 3P connector.

|