Ball Joint Removal

|

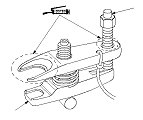

Special Tools Required

Ball joint remover, 28 mm

07MAC-SL00201

Always use a ball joint remover to disconnect a ball joint. Do not strike the housing or any other part of the ball joint connection to disconnect it.

|

|