Alternator Overhaul

|

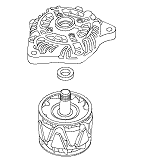

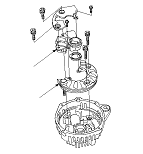

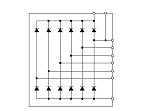

Exploded View

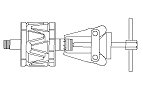

Special Tools Required

Driver handle, 15 x 135L

07749-0010000

Bearing driver attachment, 42 x 47 mm

07746-0010300

NOTE: Refer to the Exploded View as needed during this procedure.

Alternator Disassembly

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternator Brush Inspection

|

|||||||

|

|

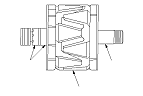

Rotor Slip Ring Test

|

|

Stator Test

|

|

|